Dynamic Bolts & Products - Yield-Lok Bolt

Design and Components

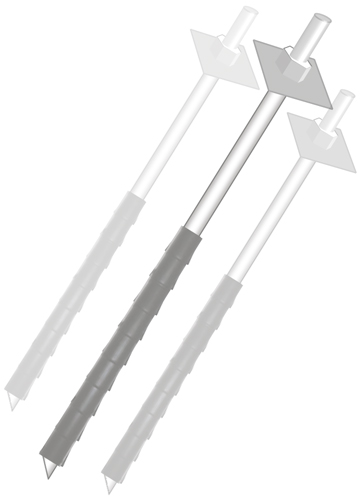

Yield-Lok bolt is made of 3/4” - Gr75 steel round bar. The bar is upset at one end to specified dimensions to achieve designed performance under static and dynamic. Upset and bar is encapsulated in engineered polymer to build the Yielding Device. End profile is stamped to aid insertion of bolt and to provide shredding of resin cartridge packaging. The bar is threaded at other end for tensioning with nut.Principle and Functions

Yield-Lok bolt is fully grouted with resin or cement in application. Resin mixing is facilitated by deformations on the head of bolt similar to rebar. The bolt provides immediate primary support on installation. YieldLok bolt can be configured to yield either in dynamic condition (YL-Dynamic Bolt) or yield at specified loads in static condition (YL-Static Bolt).YL-Dynamic Bolt

In static condition, YL-Dynamic Bolt provides stiff support similar to rebar bolt (refer to static performance curve), while in dynamic condition, the bolt yields at a constant load (refer to dynamic performance curve) to absorb dynamic energy by pulling the upset through polymer (i.e. plough effect).YL-Static Bolt

In convergence condition, YLStatic Bolt provides consistent yield at specified load by pulling the upset through the polymer. The static yielding load of bolt is controlled by varying the dimension of upset. In both dynamic and static conditions, Yield-Lok bolt provides stiff shear resistance.Technical Specifications

| Type of steel | 3/4” – Grade-75 round bar |

| Yield strength of steel | min. 75,000 psi (518 Mpa) |

| Tensile strength of steel | min. 100,000 psi (688 Mpa) |

| Elongation of steel | 8% |

| Diameter of polymer coating | 1” (25.4 mm) on average |

Yield-Lok Dynamic-Bolt

| Dynamic yield load | 7 ~ 9 Mt (= 70 ~ 90kN) |

| Dynamic yield displacement | ~ 200mm per impact at 5.4m/sec velocity with 16.4kJ input energy |

| Energy absorption capacity | 50 kJ or more with 30” (760mm) long polymer coating |

| Displacement capacity | 60mm up to the length of polymer coating |

Yield-Lok Static-Bolt

| Static yield load | 12 Mt (YL-S80 bolt), 13.5 Mt (YL-S85 bolt) |

| Displacement capacity | 760mm up to the length of polymer coating |

| Recommended drill hole diameter | 1-1/4” ~ 1-1/2” (32mm ~ 38mm) |

| Recommended resin cartridge | 1-1/8” ~ 1-3/16” (28mm ~ 32mm) |

General Features

Suitable in static and dynamic load conditions.- Applicable as primary support.

- Compatible with existing ground control system and installation machines.

- Performance independent of drill hole diameter and resin properties.

- Performance characteristics are consistent through multiple and varying amplitude of impacts.

- The engineered polymer coating performs down to -70 degrees centigrade.

Installation Procedures

Installation machine and procedures are similar to those for regular resin rebar bolt.- Drill a hole at the recommended diameter to the depth in correspondence with the bolt length.

- Flush the drill hole to remove drilling cuttings and rock debris.

- Insert an 18” long fast resin cartridge (Gel time = 30 sec.) to the toe of the hole, followed by appropriate number of slow resin cartridges.

- Push and slowly spin the bolt into the hole until the plate contacts rock surface.

- Rotate the bolt at full speed for 30~40 revolutions to mix the resin thoroughly and hold the bolt in place for at least 1 min. until the fast resin sets.

- Tension the bolt to specified torque, generally 150 ~ 200 ft -lbs.