General Requirements for Liner Plates

DSI Underground's selection of underground supports, the widest in the world, affords the contractor, the designer, and the owner a matchless combination of high performance and tunneling at low cost. One of these products alone - liner plates - offers these outstanding advantages:

- Economy of construction in time, excavation, material, manpower.

- Maximum support per given length with minimum weight of steel.

- Standard variation of plate design for all shapes of tunnels in dry or wet ground.

- Predictable strength, fire resistant.

- Continuous support during the critical mining phase in soft ground tunneling.

- Easy to store, handle and erect, whether the tunnel is straight, curved, circular, elliptical or horseshoe in shape.

- Gasket plates that seal joints, stop water leakage and reduce air loss when water is a problem.

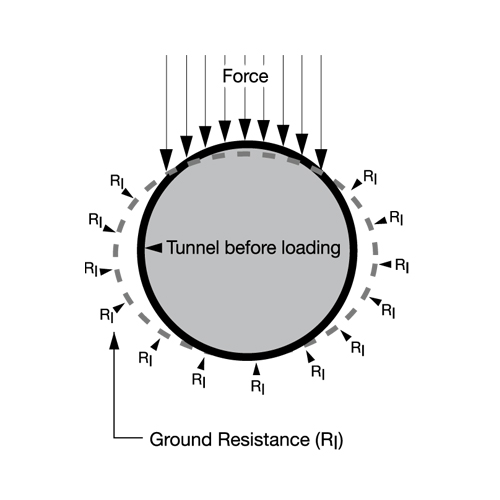

There are various methods for determining the required strength of tunnel linings. Nevertheless, the type of ground, the location and depth of cover, the size and length of the tunnel, level of ground water, superimposed loading, and history always guide these calculations.

DSI Underground liner plates can be purchased in 16" and 24" widths as corrugated or smooth plates. Liner plates are formed from one piece of metal to provide longitudinal and circumferential flanges. The plates can be galvanized and/or bituminously coated and grout holes with plugs can be included. For special conditions gasketed liner plates and tapered liner plates can also be manufactured. Liner plates can be installed alone or in conjunction with steel ribs if additional support is required.